1. Project Description

A chemical group company is a large-scale modern agricultural chemical group company integrating fertilizer production and sales, grain storage and processing, land transfer, financial services, technology research and development, and international trade.

The group is a typical capital and technology-intensive enterprise with strong continuity of production. In order to link the different link systems of office ERP, production EMS, and warehouse WMS. It is planned to build the factory's intelligent information project in stages to realize a unified production management and control platform. Because most of the production control systems of each production plant in each production workshop use modern industrial control systems such as data acquisition and monitoring and control (SCADA), distributed control system (DCS), process control system (PCS), programmable logic controller (PLC), etc. Used to control the operation of production equipment.

In order to ensure the safety of the automatic control system and the reliability of data acquisition and transmission, Houshi Network helps the chemical group to establish an industrial ring network for production data acquisition that is isolated from the management network.

2. Network Design

To provide better services for production applications, a set of production data acquisition network systems with advanced technology, strong scalability, high redundancy, and easy implementation and management will be established. It is an efficient, stable, reliable and safe production transmission platform, which can fully meet the requirements of the industrial production data acquisition system for the network support platform.

The production network system and the office network system are accessed and isolated through the Houshi industrial firewall product, and the format, command, interaction and other information of the automation control protocol message are deeply scanned to ensure that the automation equipment receives complete and safe parameter commands and ensure safe production. convoy.

3. Scheme design

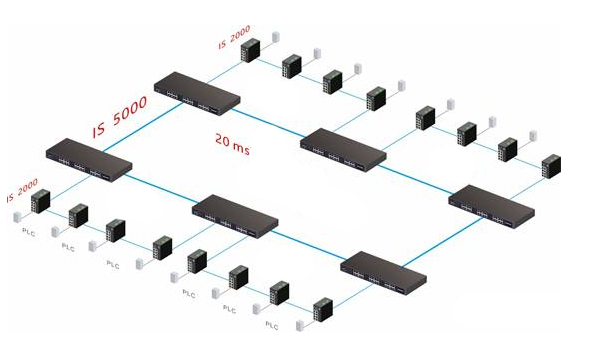

The industrial ethernet switches in the production data acquisition network of the Chemical Group use Hoshi IS2000 industrial ethernet switch and IS5000 series industrial thernet switches to form a gigabit backbone ring network, and realize the redundant connection of network links through the ring topology to ensure the reliability of the industrial network stability, and at the same time can solve the difficulty of long-distance data transmission in the vast factory area of the chemical group.

4. Network topology

5. Project Features

In order to facilitate the management of the network system, the NIS network management platform of Houshi Network conducts unified registration management and control for the data acquisition network equipment of Rising Group. Operation and maintenance personnel can conduct real-time monitoring, traffic analysis, message query, fault query and other operations on the data of data acquisition equipment in each area through the computer room management server, so as to locate faulty nodes and backup links conveniently and quickly to ensure data acquisition transmission. High stability and security of the system.

6.Why choose our industrial ethernet switches

➤ The working temperature of -40~85℃ can easily cope with the operation of ultra-high temperature environment such as steam furnace area, furnace area and disinfection area of chemical group.

➤The IP40 protection level can ensure stable operation in the continuous and high-frequency vibration environment of machinery and equipment in the finished product area, packaging area, and compression area.

➤Thecharacteristics of corrosion resistance, smoke resistance and fanless can deal with the interference of corrosion and dust in high-risk areas such as coal area, urea building, and distillation building.

➤The EMC four-level design can ensure stable and safe data collection and transmission in the case of high-intensity electromagnetic interference in the electrostatic precipitator area.

➤The design features of green and environmental protection can ensure that no harmful substances, gases and other factors are generated to the air, and highly guarantee the purpose of green environmental protection in the factory area.

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China