Description

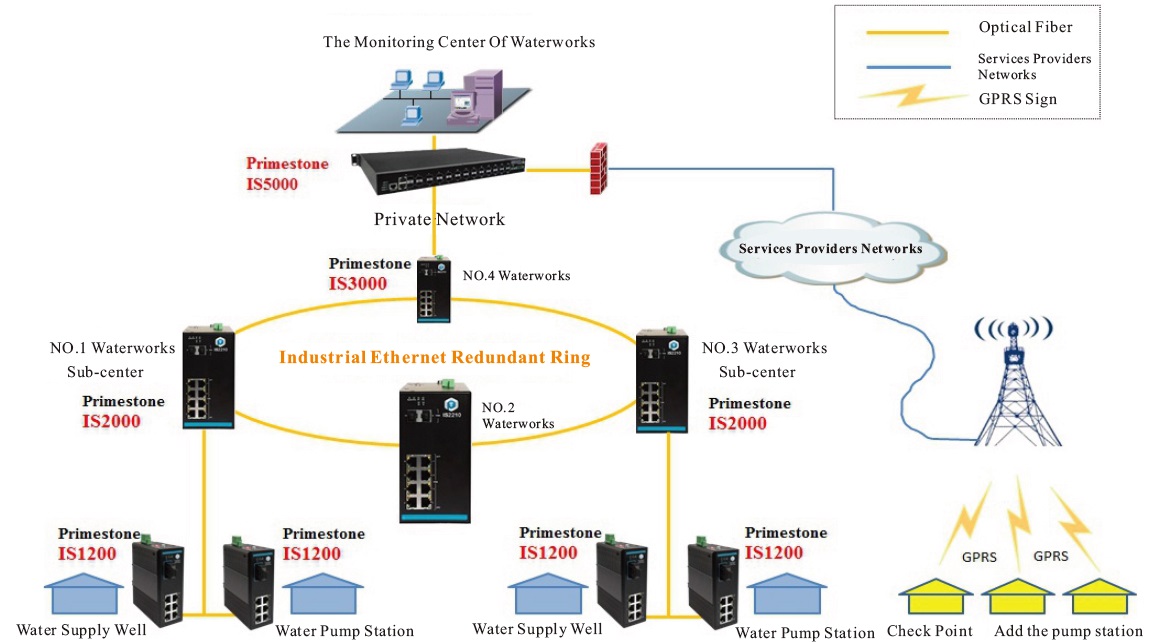

Water Supply automation system provides reliability and security for producing, to realize good quality, low power consumption and efficient water supply. Water Supply automation system is composed of upper layer software platform and under layer control units, by using of industrial ethernet switch, to monitor water supply unit(water intake pumping station, water source well, network software platform, water plant, booster pump station, water supply pipelines).to remote monitor operation data and production data from every water supply unit, remote control water pump, valves etc. Water supply automation system is composed of remote monitoring system, remote control system, remote meter reading system. Remote supervising system: monitoring the operation status and operation data, from water intake pumping station, water source well impounding reservoir, clean-water reservoir, and also remote control the start-and-stop water pump groups and valves. Remote monitoring system: monitoring important area s of water plant, ensuring work safety, and events recording. Remote meter reading system:remote collect water usage data of every client.

Requirements

Every water supply unit is decentralized, remote transmission is required High-reliability, running steady for long time Operates under high and low temperature, dustproof, damp-proof, water plant disinfection and oxidation are required Remote management, failure location, recovery Redundant network, recovery fast after fault High panel bandwidth, and high-capability of forwarding for video data transmission The industrial ehternet switch equipment installed in open circumstance, Prevent from illegal access and data destroy.

Benefits

All series optical fiber and industrial ethernet switch products, support fiber transmission High-reliability, industrial level 4 design, operating temperature from -40℃ to +85℃, dust proof, anti-salt mist, anti- vibration, anti-shocks MTBF≥10 years

Support standard network management and HouShi Network intelligent network management, remote fault location

Adopt international standard looped network protocol, ERPS ring network protection recovery<20ms

High panel bandwidth, big cache memory, to ensure video data transmission steady

High-security, support 802.1x authentication access, prevent from illegal access, different grade operation password protection, ACL control

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China